Available 24/7 via chat

Available 24/7 via chat

Regulatory standards such as OSHA’s permissible exposure limits (PELs) and ISO 45001 offer important baselines for indoor air quality (IAQ) in manufacturing environments. However, these standards define the minimum acceptable conditions, not the ideal ones. Meeting them may protect a facility from legal penalties—but not necessarily from productivity loss, quality issues, or long-term employee health concerns.

While OSHA may permit certain concentrations of airborne particulates, fumes, or volatile organic compounds (VOCs), studies show that even “legal” levels of exposure can contribute to fatigue, eye and throat irritation, and reduced cognitive performance on the production floor. Likewise, ISO 45001 requires risk management but doesn’t specify exact IAQ benchmarks, leaving it up to each facility to interpret what “safe” truly means.

The result? Many plants that meet compliance thresholds still suffer from poor air quality—and its hidden costs. These can include increased absenteeism, higher rates of rework or product defects, and premature equipment wear due to dust accumulation. Relying on the bare minimum often leads to higher long-term operational expenses.

On the other hand, plants that go beyond compliance—by implementing higher-grade filters like F7 or HEPA, using sensor-based ventilation control, and actively monitoring IAQ—consistently report gains in both performance and efficiency. Clean air isn’t just about safety; it’s about building a smarter, more resilient operation.

Standards like OSHA PELs and ISO 45001 provide essential health protections by setting exposure limits for airborne pollutants such as dust, fumes, and VOCs.

However, these regulations are designed to define minimum safety thresholds, not optimal conditions for productivity or long-term wellness. Many manufacturing plants meet the letter of the law but still experience poor air quality on the floor.

“Compliant” doesn’t always mean “safe” or “efficient.” Legal pollutant levels may still cause discomfort, fatigue, or subtle health impacts over time—leading to higher absenteeism and lower concentration. Equipment may also suffer from premature wear due to particle buildup in air-handling systems.

Sticking to the lowest standard can lead to hidden costs: increased rework, downtime, maintenance, and employee turnover.

In contrast, facilities that invest in higher-efficiency filters (like F7 or HEPA), improved airflow design, and real-time monitoring experience not only cleaner air but also better product quality, longer machine life, and stronger workforce performance.

Indoor air quality (IAQ) isn’t just about safety—it directly affects how efficiently a manufacturing plant operates. From employee health to product consistency and machine longevity, poor IAQ silently drives up costs and slows down performance.

When workers are exposed to airborne pollutants such as fine dust (PM2.5), welding fumes, or volatile organic compounds (VOCs), the risk of respiratory irritation, headaches, fatigue, and long-term illness increases. Even low-level exposure can lead to more frequent sick days, lower energy during shifts, and a rise in chronic symptoms. Over time, this not only disrupts production schedules but also increases insurance claims and turnover rates—leading to additional hiring and training costs.

Airborne particles can settle on sensitive surfaces during assembly, painting, coating, or packaging. This contamination leads to a spike in quality issues such as blemishes, misalignments, and faulty finishes—especially in precision-driven industries like electronics, automotive, or food processing. At the same time, dust and oil mist can clog HVAC coils, sensors, and internal machinery, accelerating wear and reducing the lifespan of key equipment.

Poor IAQ affects more than physical health—it also impacts mental clarity and mood. Elevated carbon dioxide (CO₂) levels or chemical odors can reduce focus, decision-making speed, and alertness. Workers may feel tired or irritable, which impacts morale and collaboration on the shop floor. In contrast, clean air has been shown to support sharper thinking, better mood, and a safer, more positive work environment.

Clean air isn’t a luxury—it’s a fundamental driver of plant-wide productivity.

Improving indoor air quality (IAQ) in a manufacturing facility requires more than just adding a few filters or cracking open a window. It’s a strategic, multi-layered approach that combines diagnostics, engineering controls, smart technology, and routine validation. Below are four proven strategies that help manufacturers move beyond compliance and toward measurable operational gains.

The first step toward cleaner air is understanding what you’re dealing with. An effective IAQ audit should include a thorough assessment of airflows, pollutant sources, filtration stages, and environmental conditions across the facility. This involves placing sensors or performing spot measurements to identify concentrations of common pollutants like particulate matter (PM1, PM2.5), volatile organic compounds (VOCs), carbon dioxide (CO₂), temperature, and humidity.

Air mapping by zone—such as welding bays, packaging lines, or clean zones—can reveal specific problem areas. Benchmarking your current conditions gives you a baseline to compare against improvement efforts and supports data-driven decision-making.

Filtration is the backbone of any IAQ improvement plan. A tiered system is typically the most effective:

G4 (coarse filters) serve as the first line of defense against large dust and debris.

F7 or F9 (fine filters) are crucial for capturing PM2.5, helping protect both equipment and workers.

HEPA filters (where required) are used in cleanrooms, pharmaceutical zones, or areas requiring ultra-clean air.

Choosing the right filters depends on your plant’s specific air quality goals, space constraints, and pressure-drop tolerances. Filters should be selected not just for efficiency, but also for their dust-holding capacity and lifecycle cost. Poor filter selection can lead to increased energy use and more frequent replacements, negating performance gains.

Ventilation isn’t just about airflow—it’s about delivering clean air where and when it’s needed. Traditional fixed-speed fans often result in over- or under-ventilation, wasting energy or allowing pollutants to accumulate. Instead, consider smart ventilation strategies like:

Demand-controlled ventilation (DCV): adjusts airflow in real-time based on sensor feedback (e.g., CO₂ levels or occupancy).

Displacement ventilation: gently pushes clean air from the floor and extracts contaminated air near the ceiling, ideal for workstations.

Heat recovery ventilation (HRV): captures heat from exhaust air to pre-condition incoming air, improving energy efficiency.

These solutions not only enhance air quality but also reduce HVAC energy consumption and support green building certifications like LEED or ISO 14001.

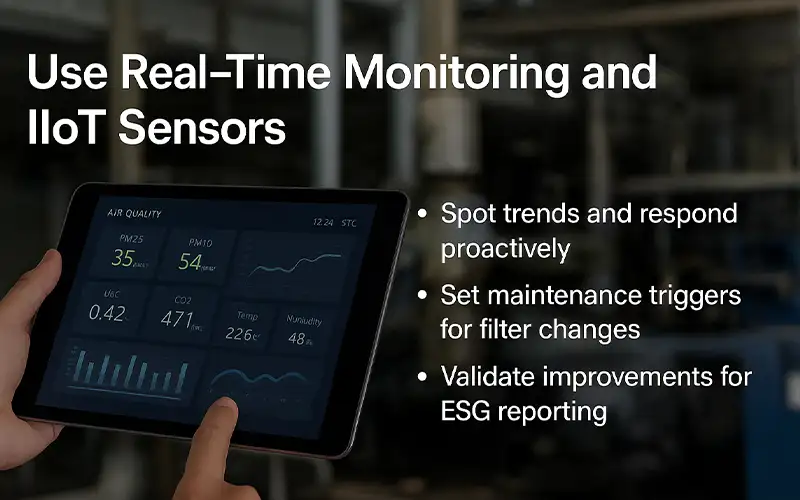

Once upgrades are in place, it’s critical to track air quality in real time. Modern IIoT-enabled sensors can monitor a wide range of IAQ metrics—including PM2.5, PM10, VOCs, CO₂, temperature, and humidity—and feed them into a centralized dashboard for analysis.

This data allows facility managers to:

Spot trends and respond proactively to rising pollutant levels

Set maintenance triggers for filter changes based on actual load, not fixed schedules

Validate improvements for ESG reporting or internal audits

Advanced systems can also integrate with building management systems (BMS) or trigger alerts when air quality dips below acceptable thresholds.

Improving air quality in manufacturing is no longer a one-time fix—it’s a continuous process of measurement, improvement, and validation. With the right mix of filtration, ventilation, and smart monitoring, plants can create healthier work environments, reduce downtime, and gain a long-term competitive advantage.

Improving air quality isn’t just a safety initiative—it’s a strategic investment that delivers measurable returns across multiple areas of plant operations. From lower energy bills to improved product quality and workforce stability, clean air impacts the bottom line in more ways than most managers realize.

Cleaner air means cleaner HVAC systems. When filters are correctly staged and airflow is optimized, equipment like coils, blowers, and heat exchangers operate more efficiently. This reduces fan energy consumption and extends maintenance intervals, leading to lower utility costs and fewer unexpected breakdowns.

Airborne particles can compromise sensitive production processes, especially in coating, packaging, electronics, and precision assembly. With better filtration and airflow control, contamination is minimized—resulting in higher first-pass yield, fewer warranty claims, and reduced scrap material costs.

Poor air quality contributes to absenteeism, fatigue, and employee dissatisfaction. A clean, well-ventilated environment supports cognitive performance, morale, and safety—factors that directly influence productivity and retention. Recruiting and retraining workers is expensive; clean air helps keep the right people on the floor.

To justify IAQ upgrades, gather baseline data on sick days, energy usage, rework rates, and HVAC maintenance costs. Then model potential gains using real improvement metrics—like kilowatt-hour savings from variable-speed fans or defect reduction percentages after filter upgrades. Clean air doesn’t just pay off—it compounds.

Clean air is no longer just a compliance requirement—it’s a critical performance factor in modern manufacturing. Facilities that treat indoor air quality (IAQ) as a strategic priority see real benefits: reduced energy consumption, fewer product defects, healthier employees, and improved operational stability.

By auditing your current air quality, upgrading filtration systems, optimizing ventilation, and using real-time monitoring, you can create a cleaner, safer, and more productive work environment. These improvements don’t just protect people—they strengthen your bottom line and support your long-term goals in sustainability, quality, and workforce retention.

Selecting the right air filters for your facilities can be a challenging task, given the variety of filter types and specifications available. If you're unsure about which filter best suits your needs, our team of experts is here to help.

With years of experience in air filtration solutions, we can guide you in choosing the ideal filter to optimize your application's performance and ensure superior air quality.

Contact us today for personalized advice and assistance tailored to your specific requirements.

$150.00 away from free shipping!

Leave a comment