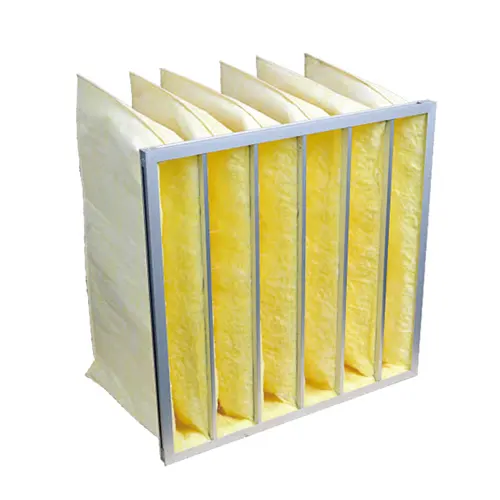

Air Filtration Products

Explore our comprehensive range of high-quality air filtration solutions designed for a variety of industries.

From HVAC filters to HEPA and industrial applications, our air filters offer superior performance, energy efficiency, and long-lasting reliability.

Find the perfect filter to meet your needs.

In the metal processing industry, effective air filtration systems are essential to protect workers from airborne contaminants like dust, fumes, and particulate matter.

In the metal processing industry, effective air filtration systems are essential to protect workers from airborne contaminants like dust, fumes, and particulate matter.