Pharmaceutical and biotechnology facilities are held to the highest standards of cleanliness and safety. Ensuring a contaminant-free environment is critical to maintaining the integrity of products and protecting both workers and consumers.

1. Contamination Risks Due to Airborne Particles, Pathogens, and Volatile Organic Compounds (VOCs)

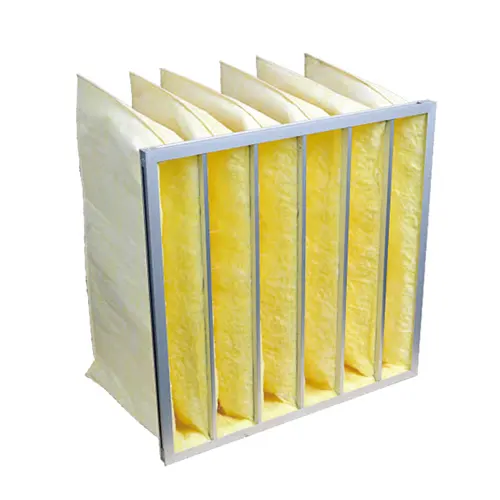

In pharmaceutical and biotech environments, airborne contaminants such as dust, bacteria, viruses, and volatile organic compounds (VOCs) can jeopardize product quality and safety. Even the smallest particles can cause cross-contamination between products or within cleanrooms, resulting in failed batches, delays, and increased operational costs.

Pathogens and VOCs can also pose health risks to workers, making it essential to prevent airborne contamination. Air filtration systems are critical for capturing these contaminants, maintaining clean air, and ensuring a sterile environment for both production and research activities.

2. Meeting Stringent Industry Regulations (GMP and ISO Standards)

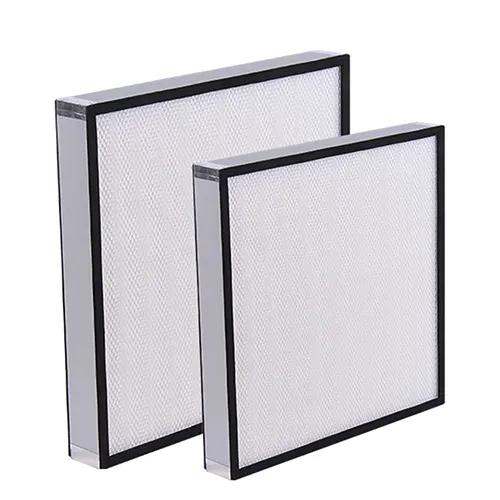

Pharmaceutical and biotechnology facilities are subject to strict regulations to ensure product safety and compliance. The Good Manufacturing Practices (GMP) and ISO standards set out specific guidelines for air quality, including particle limits and acceptable contamination levels. Facilities must maintain strict control over air quality to ensure that all products meet regulatory standards.

Failure to comply can result in fines, product recalls, or damage to a company’s reputation. Air filtration systems must be carefully selected and maintained to meet these regulatory requirements, providing consistent and reliable performance to protect both the facility and the products it manufactures.

3. Maintaining Sterile Environments for Sensitive Products

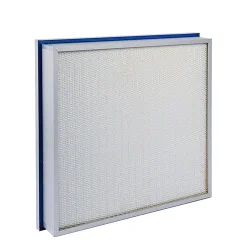

Many pharmaceutical and biotechnology products, such as biologicals, vaccines, and injectables, are extremely sensitive to contamination from the air. Maintaining a sterile environment in production areas and cleanrooms is essential to preserve the efficacy and safety of these products.

Any breach in the sterility of the environment—whether from airborne particles, moisture, or microbes—can compromise the product, leading to potential harm to patients or failure to meet quality standards.

The importance of maintaining a clean and controlled atmosphere, with continuous air filtration, cannot be overstated in the pharmaceutical and biotechnology industries.